Incinerator manufacturer

Waste Incineration

Key Statistics

Since 1985, India’s Trusted Partner for Incineration

Mc Clelland Engineers is India’s best Hazardous Waste Incinerator Manufacturer.

Incineration: An Efficient Solution for Waste Treatment

Mc Clelland incinerator manufacturer in India, specializes in high-temperature waste treatment incineartion system for solid, liquid, sludge and gaseous waste streams. Our robust, refractory-lined incinerators are engineered to ensure complete destruction of organic waste, transforming waste into inert ash and treated flue gases. Our systems are engineered for waste heat recovery, allowing clients to turn thermal energy into a profitable revenue stream. Our expertise extends to hazardous waste, chlorine handling, and precious metal recovery, backed by a dedicated service network across Maharashtra, Gujarat and rest of India.

We provide Incinerator systems designed to fulfil your waste management requirements of controlling

- NOx levels in your final discharge eflluent stream

- Dioxins levels in your final discharge eflluent stream

- Furan levels in your final discharge eflluent stream

- SOx levels in your final discharge eflluent stream

- CO levels in your final discharge eflluent stream

- HCL levels in your final discharge eflluent stream

- HF levels in your final discharge eflluent stream

Mc Clelland Incinerators are specifically designed incorporating following key features

Decades of Excellence in Incinerator Manufacturing

Since 1985, Mc Clelland Engineers, with over 350+ plants successfully commissioned across India and abroad. As India’s leading supplier of incinerators, our systems have been exported to the USA, UAE, Africa, and other regions, and our incinerators are trusted by leading industries like TATA, Reliance Industries, and Sun Pharma.

- Low NOx Burning

- Flue Gas Recirculation

- Selective Noncatalytic Reduction [SNCR]

- Waste Heat Recovery

- Flue gas cleaning

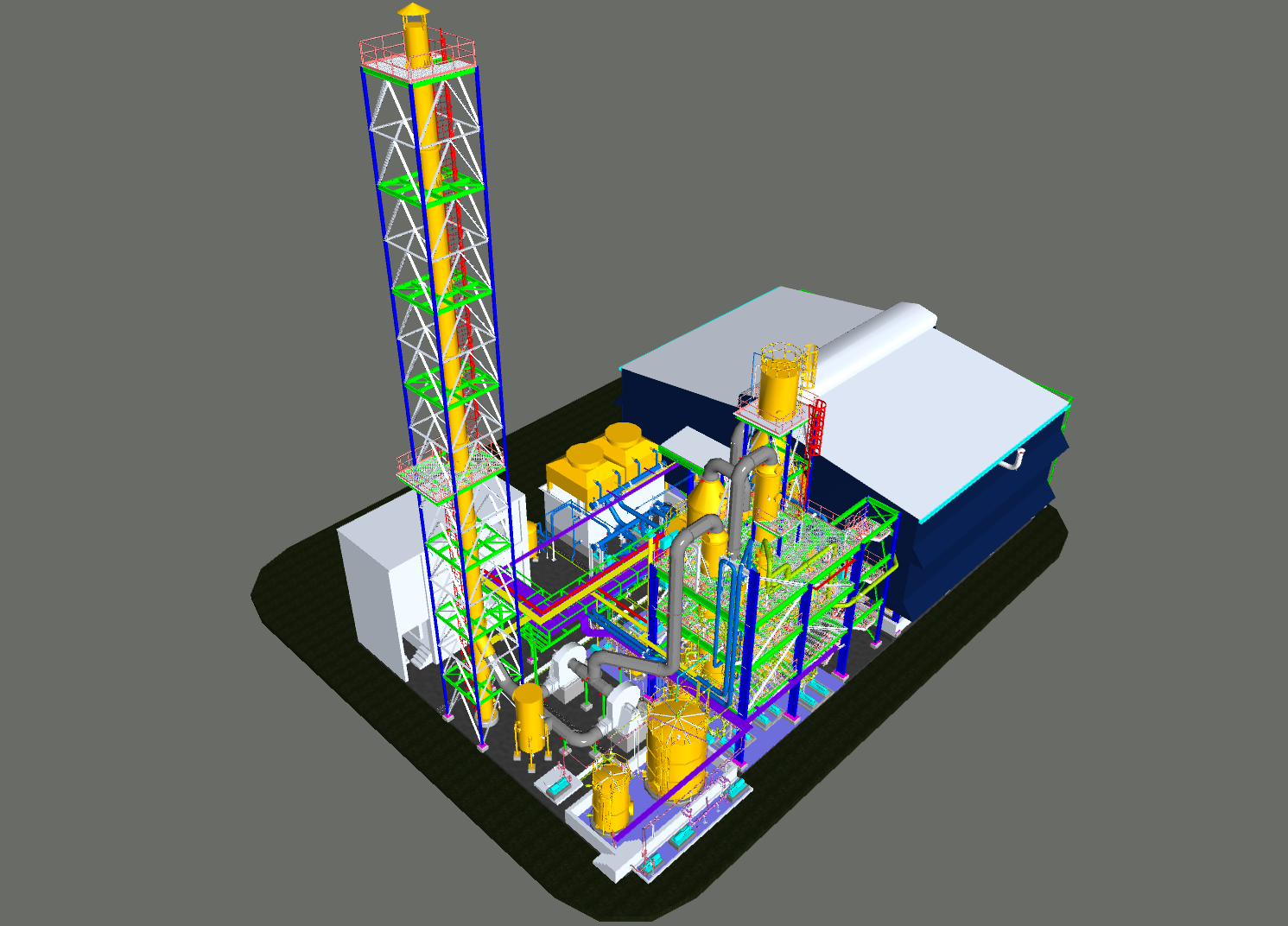

Mc Clelland uses advanced softwares to deliver excellence

Mc Clelland Engineers uses the most advanced softwares such as AUTOCAD 3D, PDMS, STAADPRO, CHEMCAD, SIMUTHERM etc. apart from in-house developed softwares such as Refractory Thermal Simulation to deliver the state of the art incineration plants.

Client’s Testimonials

TATA Steel

Toyo Industries

Teva Pharmaceuticals

Asianpaints

Dr.Reddy's Labs

Jubilant foodworks

DU PONT

Privi

SUN PHARMACEUTICAL INDUSTRIES LTD

Alembic

Delivering Excellence

Every Time

“Delivering Excellence Every Time is not just a goal, but a commitment to surpass expectations with unwavering dedication. It’s about weaving precision, passion, and a relentless pursuit of quality into every action and interaction. From the meticulous attention to detail to the relentless drive for innovation, excellence is a promise we uphold in every endeavor, ensuring that each experience is marked by unparalleled service, proficiency, and satisfaction.”

Congressional Recognition by MEMBER OF CONGRESS, USA

SIR C.V. RAMAN AWARD by County of Los Angeles, California, USA

Stiefel McClelland WTE Pvt Ltd (Swiss-India JV)

Funding from Facebook (now Meta) via Grants in 2020